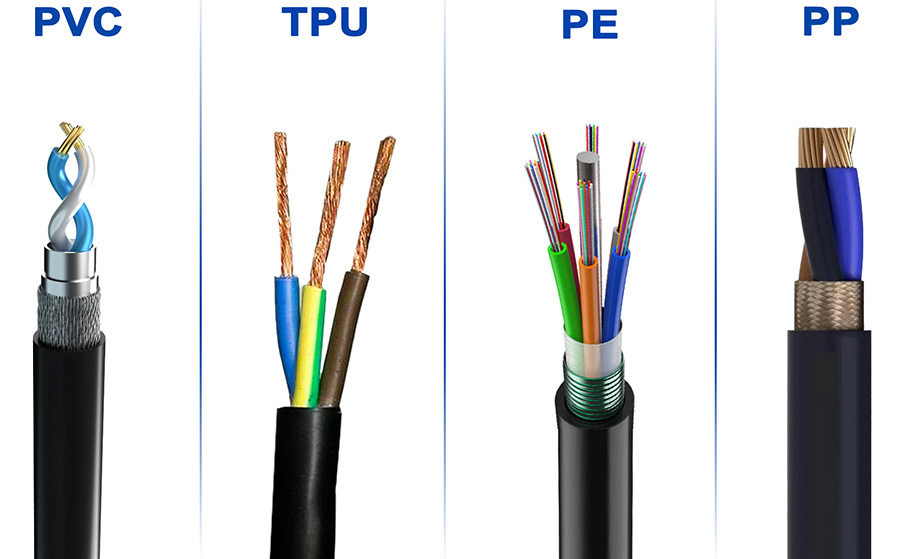

I. SIGNAL Connector Cables: In-Depth Introduction to 4 Common Materials

1.PVC (Polyvinyl Chloride):

A synthetic polymer, PVC is one of the most widely used cable materials in industrial, consumer electronics, and construction fields. Within its rated temperature range, it maintains stable insulation resistance, resisting environmental humidity and corrosion effectively. This isolates current and prevents leakage, ensuring electrical safety. Additionally, PVC offers significant cost advantages, making it a cost-effective choice.

2.PE (Polyethylene):

A common and high-performing cable material, PE exhibits minimal signal loss, making it ideal for high-frequency signal transmission. It has extremely low water absorption, resists moisture, and withstands chemicals like acids, alkalis, and salts. PE is primarily used in telecommunications, outdoor weakly corrosive environments, and humid wiring scenarios.

3.TPU (Thermoplastic Polyurethane):

A high-performance elastomeric cable material, TPU boasts excellent abrasion resistance, impact resistance, and tear resistance. It suits applications prone to material wear, such as industrial automation, mobile devices, and automotive interiors. TPU also resists water, oil, and chemicals, enabling stable performance in environments with oils, solvents, and various chemical media.

4.PUR (Polyurethane):

PUR delivers exceptional mechanical properties. It features outstanding abrasion resistance, cut resistance, and tear resistance, maintaining high flexibility even at low temperatures. This makes PUR cables particularly suitable for dynamic applications involving constant movement and bending, such as drag chains. In robotics, PUR control cables can endure millions of bending cycles or strong torsional forces.

II. Comparison of Key Indicators for SIGNAL’s 4 Cable Materials

1.Flexibility:

TPU and PUR are ideal for dynamic scenarios due to their strong flexibility and resistance to repeated bending—their abrasion resistance is 5 to 8 times that of PVC. In contrast, PVC and PE are relatively rigid, unsuitable for repeated bending, and only fit for fixed installations.

2.Long-Term Temperature Resistance Range:

PVC: -15°C to 80°C (prone to brittleness at low temperatures and softening at high temperatures).

TPU: -40°C to 90°C.

PE: -40°C to 80°C (with better low-temperature resistance).

PUR: -40°C to 90°C.

3.Chemical and Environmental Resistance:

PE excels in acid/alkali resistance and water resistance, with outstanding insulation performance.

TPU resists mineral oils (e.g., engine oil, lubricants) but not strong solvents like acetone.

PVC has the poorest resistance to oils and strong solvents, prone to swelling upon contact.

PUR offers good chemical and oil resistance, paired with high flexibility.

4.Cost Budget:

Cost ranking of the four materials: PVC < PE < PUR < TPU.

III. Selection Guide for Typical Cable Scenarios

1.Industrial Automation:

PVC: Suitable for fixed wiring in workshops, offering cost-effectiveness.

TPU: Ideal for applications with frequent bending (e.g., robot arms) or drag chain systems—8 times more abrasion-resistant than PVC, enhancing durability.

PUR: Fits diverse and harsh environments, including industrial robots, automated production lines, large machine tools, steel, and chemical industries (PUR cable harnesses are common here).

2.Automotive Industry:

TPU or PUR: Suitable for engine compartments with oil and gasoline vapor corrosion.

TPU: Preferred for cabin wiring requiring high flexibility and frequent disassembly/reassembly.

PE: Optimal for chassis wiring harnesses, resisting gravel impact and mud erosion with superior chemical and water resistance.

3.Telecommunications:

PE: Fits outdoor fixed wiring and high-speed data transmission—resists cracking/powdering under sunlight and has a low dielectric constant (2.3), reducing high-frequency signal loss.

4.Food Processing:

TPU: Suitable for direct food contact applications.

PVC: Fits dry area fixed wiring in food processing plants, offering lower cost.

SIGNAL connector cables utilize high-quality materials including PUR, PVC, TPU, and PE, professionally matched to diverse application scenarios and harsh environments. This ensures reliable, long-lasting, and cost-effective connection solutions under complex working conditions. Selecting the right cable material is critical to ensuring long-term stable equipment operation and enhancing safety performance.